Screw Air Compressor

Screw air compressors are a popular choice for many industries due to their high efficiency and reliability. They work by using two rotors to compress and pressurize air, which is then stored in a tank for later use. This method of compression results in less heat generation and lower energy consumption compared to other types of air compressors. Screw air compressors are also known for their ability to operate continuously without the need for frequent maintenance or downtime, making them ideal for industries that require constant compressed air supply. At C & T Enginnering (Pvt) Ltd, we offer a range of screw air compressors that are designed to meet the specific needs of your operations, providing you with a reliable and efficient compressed air solution.

Load / Unload Control Mode to Reduce Energy Consumption

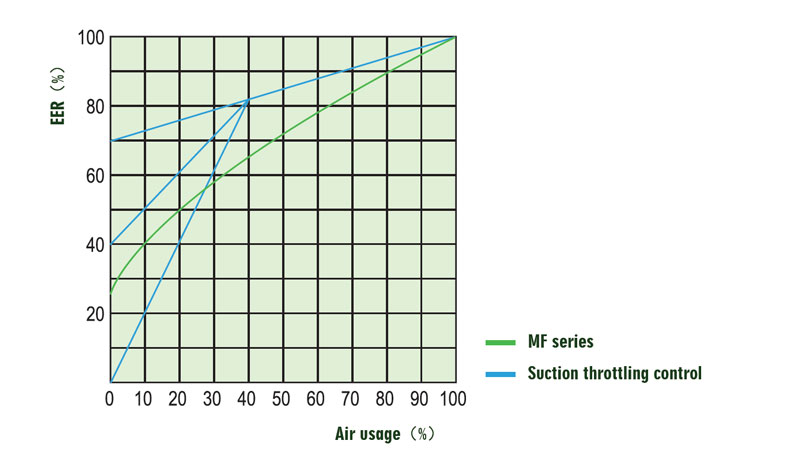

Compared with the previous suction throttling method, the new type of loading and unloading controls has better characteristics without load. In addition, the suction regulating valve with larger control load adopts special alumina membrane treatment method, and ensures the stable supply of compressed air and energy saving by switching between loading and unloading.

Performance & Feature

- Improve power & increase exhaust capacity

- Improve air intake filtration to ensure clean air

- Improve inspiratory pressure loss

- Improve exhaust pressure loss

- Reduce the inspiratory temperature

Energy-saving performance curve

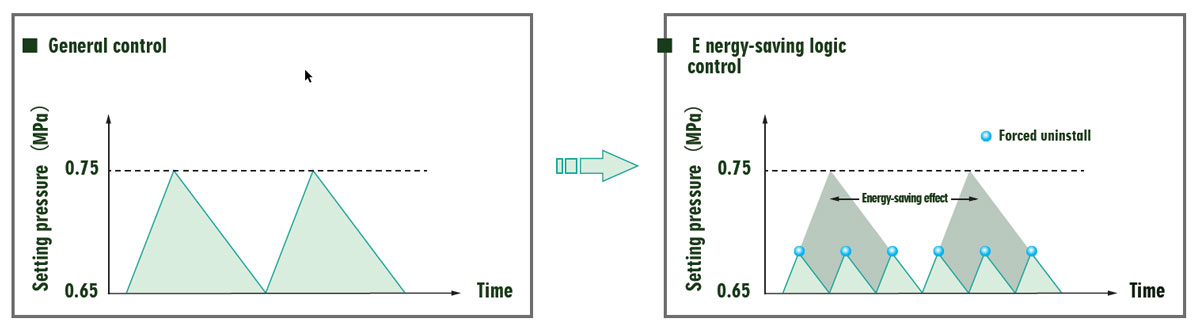

The Best Control & Saving Energy

After a certain load time, using the energy saving logic that can be forced to load, to control unnecessary step-up, the maximum energy saving effect of 6%.

Compared with the previous suction throttling method, the new type of loading and unloading controls has better characteristics without load. In addition, the suction regulating valve with larger control load adopts special alumina membrane treatment method, and ensures the stable supply of compressed air and energy saving by switching between loading and unloading.

High Quality, Efficiency Motor

The motor be processed and commissioned according to high-level requirements, especially special treatment on the frequency conversion motor and plateau motor , each motor have been strictly tested. The motor is equipped with heavy SKF imported bearings. The two ends of the bearing housings are equipped with grease filler mouth, which is convenient for maintenance, and fully embodies the humanization of the design. Because of the high protection level, the dust and water can be effectively prevented from entering the motor, and the service life of the motor is prolonged.

Unique Rational Layout

The machine be designed with electrical integration, it is easy for handling and installation. The inner space of the machine is divided into hot and cold chambers, the internal air circulation is reasonalbe, ensure the sufficient cooling of parts and prolong the service life. In order to reduce the noise of the machine, a fully enclosed removable cabinet has been designed. It contains high quality flame retardant sound insulation sponge, which makes you more flexible in considering the placement of air compressor. Not only in line with environmental protection requirements, but also facilitate the cleaning of the machine.

High Efficiency, Energy-Saving Screw Type Air End

The host is made of excellent, unique design and precision manufacture. The design of profile optimization reflects the high efficiency and durability, optimization of rotor meshing line maximum, reduce the leakage triangle area, further improve the volumetric efficiency, with a large diameter rotor and the best ratio of length to diameter, ensure the high efficiency and low power output. Unique bearing arrangement, both ends of the rotor are supported by a fixed radial bearing and a flexible and reliable direct thrust bearing. High quality, large size SKF heavy-duty bearing design, greatly extended the service life. The lip type bearing with slotted inner ring adopts high precise size and quality material, and has the function of pumping and preventing leakage.

Reliable Direct Drive

The air compressor with power more than 55kw by elastic coupling and a center bracket and host motor will be combined into one, to ensure in the transportation, installation and operation of the motor and the permanent host, reducing the starting torque, achieve the lowest energy consumption and minimal maintenance workload.